Sustainable, Demand-responsive Pumped Hydroelectric Storage (PHS) Using Onsite-manufactured Pipe

As the world moves away from fossil fuels to greener and more sustainable energy sources, solar and wind energies gain popularity.

These technologies require large storage devices to save/store the energy produced during off-peak hours for later use in times of higher demand. Recent studies have proven that we do not likely possess enough materials in the world to simply build giant lead-acid (or nickel-based or lithium-based) batteries to do the job.

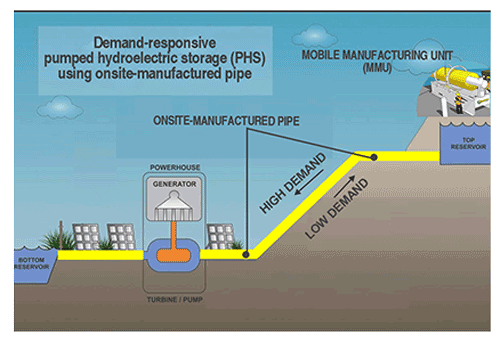

A great simple technology that is sustainable and can address this need is Pumped Hydroelectric Storage (PHS) shown here.

How PHS Works

A sustainable PHS hydropower system is comprised of two bodies of water: One at a higher elevation, atop a hill or mountain; and another body of water at a lower elevation, such as a lake or reservoir.

During times when energy demand is low, the excess electricity generated is used to pump water through a pipe (or penstock) uphill from the reservoir at the lower elevation. The water is then stored in the higher reservoir until the next peak demand time.

During peak times when energy demand is high, water from the higher source is released to flow downhill through the penstock to the lower elevation reservoir. This water flows through a turbine near the bottom of the penstock and generates electricity.

In short, the PHS system utilizes a solar- or wind-powered pump for pushing the water uphill, and a turbine to create electricity when the water runs downhill for peak usage times.

How Many Pipes Needed?

The same penstock can be used for uphill and downhill flow when the pump is bypassed during peak generating hours for downhill water flow, and the generator turbine is bypassed during slower uphill pumping.

Alternatively, separate pipes can be used: One designated pipe that passes through the turbine for the more rapid downhill water flow, generating electricity; and another pipe for the slower water pumping going uphill during non-peak hours, using an on-site sustainable energy source such as solar or wind power.

Conveyance System is Key

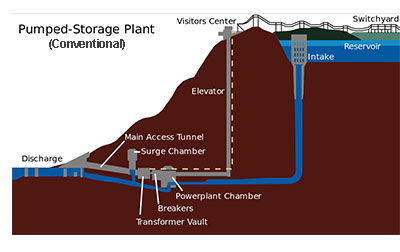

A major component of PHS is the pipe or penstock that runs along the sloping surface of the hill or mountain. These pipes must be designed to resist high pressure levels. In many cases there is no existing roadway on the hillside that would facilitate the delivery and assembly of factory-produced pipes to build the penstock. As a result, the piping or water conveyance system resembles the one shown in Fig. 1b that includes a vertical and a horizontal pipe.

These projects can become very costly as the drilling of these tunnels and placement of the pipes require significant equipment.

There is, fortunately, an economical solution for construction of PHS systems and the penstock (pipe) needed for such projects.

Economic Feasibility

The use of conventional pipes would make the PHS solution cost-prohibitive. The manufacturing, transportation, excavation and location accessibility all combine to drive installation costs out of reach, resulting in low return on investment or ROI that ar not attractive.

We propose to manufacture -- directly on-site -- a durable, lightweight pipe long enough to connect one reservoir to the other while maintaining flow requirements of the system. The pipe can be made near the upper reservoir and it is being manufactured the finished pipe is pulled along the sloping hill towards the lower reservoir.

This low-cost solution is possible thanks to the on-site manufactured InfinitPipe®, first introduced by Ehsani in 2012 after several years of development by Ehsani’s company, QuakeWrap, Inc.

This lightweight FRP pipe manufacturing system would connect the needed components for the system – two bodies of water at differing elevations, electrical generator with turbine pump, solar or wind powered pump for returning water to the original location during off-peak hours – results in an environmentally sustainable energy solution requiring minimal daily maintenance service disruption.